When operating a construction hoist lift, safety must always come first. Whether you're using it to transport heavy materials or move workers up and down high-rise buildings, any oversight in safety can lead to serious accidents, project delays, or legal penalties. At GYT, we manufacture and supply construction hoist lifts that are built with safety and reliability in mind—but proper operation is equally essential. In this article, we’ll guide you through a comprehensive safety checklist and best practices, so you can ensure every use of your construction hoist lift is secure and compliant.

Why Safety Is Critical for Construction Hoist Lifts

Real Risks of Misuse

Construction hoist lifts are powerful machines that bear significant weight and operate at great heights. When used improperly or without sufficient inspection, they pose serious risks such as:

Structural Collapse: Overloading the hoist or using it without proper anchoring and tie-ins can cause the entire system to fail.

Falling Loads: Unsecured materials or malfunctioning platforms may result in falling debris that endangers workers below.

Personnel Injury: Operators and passengers may face injuries due to jerky motion, sudden stops, faulty doors, or malfunctioning brakes.

Accidents are not rare. Globally, construction lift failures account for a noticeable share of site injuries and fatalities. The consequences go beyond the physical—legal liabilities and reputational damage also follow. That’s why a proactive safety checklist isn’t optional—it’s a fundamental requirement.

Industry Standards & Regulations

Construction hoist lifts must comply with strict national and international safety regulations. Some of the most widely enforced standards include:

OSHA (Occupational Safety and Health Administration): In the U.S., OSHA mandates specific regulations for hoist operation, maintenance, and inspection.

CE Marking: European Union markets require CE certification to verify equipment meets health and safety requirements.

ISO Standards: These offer global safety benchmarks, including mechanical reliability and electrical systems safety.

Local Authority Guidelines: Most regions require periodic third-party inspections, certifications, and installation permits before and during use.

Understanding these regulations—and choosing a supplier like GYT that complies with them—is the first step in ensuring safe operations.

Daily Safety Checklist for Operators

Creating a culture of safety starts with daily routines. The following checklist is designed for hoist operators and on-site maintenance teams to follow each day before operations begin.

Pre-Operation Visual Inspection

Before switching on the hoist, perform a comprehensive visual check of all key components. Look for:

Motor and Gearbox Condition: Ensure there are no oil leaks, unusual vibrations, or signs of wear.

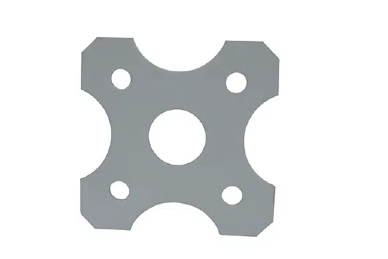

Rack-and-Pinion Mechanism: Check for proper alignment, cleanliness, and lubrication of gears.

Cables and Wiring: Look out for fraying, loose connections, or exposed wires near the control panels or power sources.

Control Box: Verify that the user interface, switches, and emergency buttons are intact and responsive.

Doors and Safety Locks: All doors should close securely and only open at designated stop levels.

This routine should be done by certified personnel and documented in the daily log for accountability.

Load Check and Balancing

Even though construction hoist lifts are engineered to handle heavy loads, overloading or uneven distribution can lead to dangerous consequences. To prevent this:

Never Exceed Rated Capacity: Always refer to the manufacturer’s specifications for maximum weight limits.

Ensure Load Stability: Loose or unbalanced cargo may tilt the platform, stressing the mast and risking toppling.

Confirm Passenger Limits: For personnel hoists, ensure the number of occupants is within safe limits.

GYT’s hoists are equipped with weight monitoring systems, but human oversight remains critical for added protection.

Safety Systems Functionality

Every hoist is built with multiple safety systems. Each one must be tested before daily use:

Braking System: The mechanical and electrical brakes should activate properly during manual testing.

Emergency Stop: Test the red emergency button to ensure the lift halts immediately and safely.

Door Interlocks: These prevent the hoist from moving if any door is not properly closed and locked.

Limit Switches: Ensure the hoist doesn’t exceed its upper or lower travel limits.

A failure in even one of these systems can lead to uncontrolled movement, so regular inspection is non-negotiable.

Best Practices for Site Managers

Safety goes beyond mechanical checklists. Site management plays a huge role in ensuring construction hoist lift operations remain controlled, compliant, and predictable.

Training Protocols

Untrained or undertrained operators are one of the leading causes of hoist-related accidents. It’s the site manager’s duty to enforce strict training programs:

Operator Certification: Ensure that every lift operator has completed relevant certification and hands-on training.

Daily Briefings: Begin each day with a quick safety meeting to review hazards, weather impacts, or unusual site conditions.

Emergency Procedures: All personnel should know what to do in the event of a malfunction, power outage, or evacuation.

GYT offers training support and technical documentation to help clients implement effective training protocols that reduce risk.

Signage, Fencing, Supervision

Controlling the surrounding area of the construction hoist lift is equally important:

Warning Signs: Clearly mark loading zones, danger areas, and operation limits with durable signs.

Protective Fencing: Use fences or barriers to keep unauthorized personnel and pedestrians away from the lift area.

Dedicated Supervisor: Assign an experienced lift supervisor to oversee operations during active use.

It’s also smart to place a logbook or checklist near the control panel so each operator confirms completion of checks.

Advanced Safety Enhancements Worth Considering

Beyond basic safety, there are additional technologies and processes that can dramatically improve site safety:

Remote Monitoring Systems: Some modern hoists can be integrated with IoT technology, allowing managers to monitor lift status, usage patterns, and alerts from a central dashboard.

Wind and Weather Sensors: Environmental conditions can affect hoist stability. Smart sensors can trigger automatic stoppage when wind speed exceeds safe limits.

Load Detection Alarms: Advanced systems issue audible warnings if overload conditions are detected before the lift engages.

Investing in these features may reduce long-term costs by preventing accidents and minimizing repair downtime.

Case Example: Avoiding a Near-Miss Incident

A real-world example underscores the importance of following safety protocol:

At a mid-rise residential construction site in Southeast Asia, a GYT construction hoist lift was being used to transport formwork to the 10th floor. During a routine morning check, the site supervisor noticed an unusual noise from the rack-and-pinion mechanism. After halting operations and calling the maintenance team, they discovered a damaged gear tooth that could have caused a serious malfunction mid-operation. Because the site followed daily checklists diligently, a dangerous incident was avoided.

This example demonstrates how regular inspections, paired with responsive equipment design like that from GYT, create a strong safety net.

Conclusion

Operating a construction hoist lift without a comprehensive safety checklist is a risk no site should take. From pre-operation inspections to load management, safety systems, and site-wide management protocols, every aspect must be treated as critical. GYT’s construction hoist lifts are designed with safety at their core, but equipment is only as safe as its use allows.

Before you purchase or rent a construction hoist lift, be sure your team is trained, your processes are standardized, and your checklist is followed every single day. These steps can save time, protect your workers, and prevent costly accidents.

For technical consultation, product specifications, or safety feature support, don’t hesitate to contact us today. Let’s build safely—together.