Introduction to Tower Cranes

In the realm of modern construction, tower cranes stand as towering symbols of progress and engineering marvel. These colossal machines are not just tools; they are the backbone of large-scale building projects, enabling the vertical and horizontal movement of heavy materials with unparalleled efficiency. As urban landscapes continue to evolve, the role of tower cranes becomes increasingly pivotal, shaping the skylines of cities worldwide.

The history of tower cranes is a testament to human ingenuity. From the simple block and tackle systems of ancient civilizations to the sophisticated, computer-controlled giants of today, tower cranes have undergone a remarkable transformation. This evolution reflects broader trends in construction technology and the growing demands of the industry for faster, safer, and more efficient building methods.

Understanding the mechanics and applications of tower cranes is crucial for anyone involved in the construction industry. These machines are not only complex in their engineering but also critical in ensuring that projects are completed on time and within budget. As we delve deeper into the world of tower cranes, we will explore their various types, key components, and the factors that influence their selection and operation on construction sites.

The Mechanics of Tower Cranes

At the heart of every tower crane is a sophisticated system designed to lift and move heavy loads with precision. The basic mechanics of a tower crane involve a combination of a vertical mast, a horizontal jib, and a counterweight. The mast provides stability and height, allowing the crane to reach impressive elevations. The jib, which extends horizontally from the mast, is where the lifting action occurs. By rotating around the mast, the jib enables the crane to move loads over a wide area.

Powering these massive machines is a combination of electric and hydraulic systems. Electric motors drive the crane’s movements, from hoisting to slewing. Hydraulic systems, on the other hand, provide the necessary force to lift heavy loads. The synergy between these power systems ensures that tower cranes operate smoothly and efficiently, even under the most demanding conditions.

Safety is paramount in crane operations, and modern tower cranes are equipped with advanced safety features. Load limiters prevent overloading, while anti-collision systems ensure that multiple cranes on a site do not interfere with each other. Additionally, remote control operations and automated safety checks have become standard, minimizing the risk of human error and enhancing overall safety on construction sites.

Types of Tower Cranes

The construction industry has a diverse array of tower cranes, each designed to meet specific project requirements. According to the article “How Do Tower Cranes Work?”, the primary distinction among tower cranes lies in their design and operational capabilities. Static tower cranes, also known as fixed cranes, are commonly used in large construction projects. These cranes are anchored to the structure being built and are ideal for sites where the crane’s height can be increased as the building rises.

On the other hand, mobile tower cranes offer greater flexibility. These cranes are mounted on wheeled or tracked chassis, allowing them to be towed to different locations as needed. While they may not reach the same heights as static cranes, their mobility makes them invaluable for projects that require frequent repositioning of the lifting equipment.

Within these broad categories, tower cranes can be further classified based on their lifting mechanisms and jib designs. Hammerhead cranes, for instance, feature a horizontal jib that resembles a hammerhead, allowing for efficient load placement. Luffing cranes, with their angled jibs, are particularly suited for tight spaces where the crane’s footprint needs to be minimized. Each type of tower crane brings its own set of advantages and is chosen based on factors such as load capacity, reach, and the specific constraints of the construction site.

Key Components of Tower Cranes

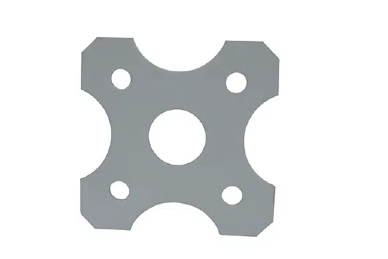

The operation of a tower crane relies on several key components, each playing a critical role in the machine’s overall functionality. According to the article “Tower Crane Components”, the hook and hook block assembly is perhaps the most crucial. This is where the lifting action occurs, with the hook designed to securely hold and lift heavy loads. The hook block, which includes multiple sheaves, reduces the amount of force needed to lift a load, making the crane more efficient.

The trolley and hoist mechanism is another vital component. The trolley moves along the jib, allowing the operator to position the load precisely. The hoist, which is powered by an electric motor, raises and lowers the load via a wire rope or chain. This system is designed to handle the immense weight of construction materials, ensuring smooth and controlled lifting operations.

Power and control systems are the brains behind a tower crane’s operation. These systems manage the crane’s movements, from lifting and lowering to rotating and extending the jib. Modern tower cranes are equipped with sophisticated control systems that allow for precise maneuvering, even in challenging conditions. Additionally, these systems include safety features such as overload sensors and emergency stop mechanisms, ensuring safe operation at all times.

Factors Influencing Tower Crane Selection

Selecting the right tower crane for a construction project is a critical decision that can impact the project’s success. According to the article “How to Choose the Right Tower Crane for Your Construction Project”, several key factors must be considered. The first is the site’s spatial constraints. In urban environments, space is often at a premium, making it essential to choose a crane that can operate efficiently within the available area. Luffing cranes, for example, are designed to operate in tight spaces by adjusting the angle of the jib, thus minimizing their footprint.

Load capacity is another crucial factor. The crane must be capable of lifting and moving the heaviest loads required for the project. This not only ensures operational efficiency but also enhances safety, as overloading a crane can lead to catastrophic failures. Additionally, the height and reach of the crane must be considered, ensuring that it can adequately serve the entire construction site.

Finally, the project’s timeline and budget will influence the choice of crane. Some projects may require the rapid deployment of a mobile crane, while others may benefit from the extended capabilities of a static crane. Cost considerations also play a significant role, with factors such as rental rates, maintenance costs, and potential downtime being carefully evaluated to ensure the crane selection aligns with the project’s financial constraints.

The Future of Tower Cranes in Construction

The future of tower cranes in construction is poised for significant advancements, driven by technological innovation and evolving industry demands. According to the article “The Future of Tower Cranes: Innovations and Trends”, one of the most promising developments is the integration of smart technologies into crane operations. These technologies include IoT sensors, which provide real-time data on load weights, wind speeds, and operational efficiency. This data can be used to optimize crane performance, enhance safety, and reduce downtime.

Automation is another trend shaping the future of tower cranes. Automated cranes can operate with minimal human intervention, reducing the risk of accidents and improving operational efficiency. These cranes can be programmed to perform specific tasks, such as material hoisting and placement, with precision and consistency. Furthermore, advancements in remote control technologies are enabling operators to manage multiple cranes from a single control center, enhancing coordination and reducing the risk of collisions.

As the construction industry continues to evolve, tower cranes will play a pivotal role in shaping the future of urban development. With their unparalleled lifting capabilities and adaptability to various project requirements, tower cranes will remain indispensable tools in the construction arsenal. As we look ahead, the continued integration of smart technologies and automation will undoubtedly enhance the efficiency, safety, and sustainability of tower crane operations, ensuring their relevance in the ever-changing landscape of modern construction.