Understanding how a construction hoist lift operates is key to choosing the right equipment for your job site, especially when dealing with high-rise projects or demanding infrastructure developments. A construction hoist lift is an essential vertical transport solution that moves personnel and materials efficiently and safely along the side of buildings. At GYT, we manufacture a variety of construction hoist lifts engineered for durability, safety, and ease of use. In this article, we will walk you through the internal systems, mechanical design, and operational workflow of a construction hoist lift—step by step—to help you make informed decisions for your next project.

Construction Hoist Lift Working Principle

Rack-and-Pinion Drive System

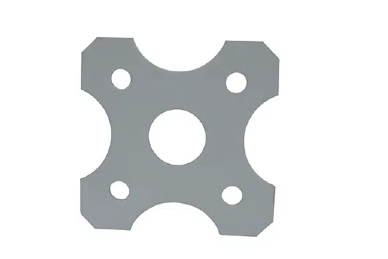

At the heart of every construction hoist lift is the rack-and-pinion drive system, a highly reliable mechanical structure that ensures vertical movement with precision. The system includes a gear (pinion) attached to the hoist’s motor, which engages with a stationary steel rack fixed along the vertical mast.

As the motor activates, the pinion turns and climbs the rack, allowing the hoist cage to move up or down. This method eliminates the need for ropes or pulleys, making the system not only easier to maintain but also more secure under heavy loads and frequent operation.

Compared to older cable or pulley-driven systems, the rack-and-pinion mechanism delivers better control, consistent speed, and lower risks of sudden drops or slippage. It is particularly useful in high-rise construction, where precision and safety are critical.

The gearbox, mounted near the motor, helps regulate torque and maintains a balanced transmission of power, ensuring smooth acceleration and deceleration of the hoist cage.

Electrical and Safety Systems

Beyond the mechanical drive, a construction hoist lift is supported by a comprehensive electrical control system. This includes control panels that allow operators to manage speed, direction, emergency stops, and floor selection. Most modern hoists are equipped with programmable logic controllers (PLC) that enable automatic floor stopping, speed regulation, and fault diagnosis.

One of the most critical aspects of the safety system is the limit switch, which prevents the cage from going beyond the top or bottom of the mast. If the operator fails to stop in time, the limit switch will cut off power to the motor, preventing over-travel.

In addition, electromagnetic braking systems are integrated to stop the cage immediately in emergencies. If power is lost, the brake activates to hold the cage in place. Emergency lowering devices and overload detection systems are also commonly included, providing multiple layers of safety for both personnel and cargo.

Some hoists are also equipped with interlock door mechanisms, which ensure the hoist will not operate unless the cage doors are fully closed—further enhancing site safety.

Mechanical Structure Breakdown

Mast and Tie-In

The mast, usually made of high-strength steel, forms the vertical path along which the hoist cage travels. It is installed in modular sections, allowing the system to be extended as the building rises. These sections are bolted together on-site and anchored to the structure using tie-ins at regular intervals to ensure stability and reduce vibrations.

The distance between tie-ins varies depending on hoist height, local regulations, and wind load requirements. Properly installed tie-ins are crucial, as they prevent lateral sway and ensure a smooth and straight vertical travel path.

The mast base is secured on a solid concrete foundation, and the initial mast sections are erected with a crane or forklift before the hoist cage is attached. The hoist climbs the mast using its rack-and-pinion system, and additional mast sections can be added as needed.

Cage Design

The cage, or cabin, is the part of the hoist that carries personnel or materials. GYT offers various configurations, including single-cage or twin-cage designs, depending on the site's capacity and access requirements.

Cages are built from welded steel with protective mesh or enclosed walls. Inside the cage, load platforms may be included to stabilize materials. Entry can be from one or more sides, and sliding doors, roller doors, or swing doors are used depending on design preference.

For projects involving people, cages include lighting, ventilation, handrails, and emergency intercom systems. For material-only hoists, cages are usually simpler, focusing on load volume and floor durability. All cages undergo rigorous testing to meet international safety standards.

Some advanced hoists also offer frequency converters (VFCs), which allow for smoother acceleration and more precise speed control—ideal for transporting fragile or sensitive materials.

Installation and Operation Process

Initial Setup

Installing a construction hoist lift begins with careful site preparation, ensuring a flat and stable surface to support the mast base and cage. A concrete base is typically poured weeks in advance to allow full curing before mast assembly begins.

The mast erection starts with placing the base section, followed by anchoring the next segments one at a time using bolts and tie-ins. The cage is then mounted onto the rack system and connected to the drive motor, gear system, and control panel.

Following physical installation, electrical calibration is carried out to ensure limit switches, brakes, and control buttons function properly. Technicians test the hoist’s movement across all mast levels before it is cleared for use. Proper alignment and load testing are crucial at this stage to prevent future operational issues.

During setup, safety signage and operator training materials are typically posted near the hoist base, especially for multi-contractor job sites.

Daily Operation

Once installed, a construction hoist lift becomes an integral part of the daily workflow. It helps schedule vertical movement for labor teams, reduces reliance on manual lifting, and optimizes delivery of materials to specific floors.

Operators monitor load weight using built-in sensors, ensuring the cage is not overloaded beyond rated capacity. The lift can be configured to operate at various speed settings depending on the size and weight of the load.

In multi-cage setups, synchronized operation can be controlled using digital interfaces to avoid cage collision or power overload. Some systems allow RFID or access card-based entry, allowing only trained personnel to operate the lift.

Maintenance logs are usually kept daily, checking motor oil levels, inspecting gears, verifying electrical connections, and cleaning the rack and pinion from dust or debris. These procedures ensure smooth and continuous performance throughout the project duration.

Dismantling Safely

At project completion, dismantling the hoist involves a reverse installation process. The cage is brought to ground level, disconnected from the drive system, and removed. Mast sections are then unbolted and lifted away using cranes or forklifts.

Tie-ins are carefully removed from the building, ensuring no structural damage. Safety checks are performed throughout to ensure no parts are left behind or improperly stored. Electrical panels and wiring are disconnected and repackaged for future use or return if rented.

GYT provides technical support during dismantling as well, ensuring our hoists can be efficiently moved to the next project without unnecessary delays or costs.

Conclusion

Understanding how a construction hoist lift works—from the rack-and-pinion system and electrical controls to cage design and installation—is essential for selecting and using the right equipment for your construction project. These lifts provide a safe, efficient, and reliable method for vertical transportation on complex job sites.

At Fuzhou Guangyitong Mechanical Equipment Co., Ltd. (GYT), we specialize in delivering advanced construction hoist lift solutions tailored to your project’s needs. By mastering the internal mechanisms and safety systems of our equipment, you ensure better performance, reduced downtime, and improved worker safety.

Whether you’re managing a commercial high-rise, infrastructure build, or residential tower, a well-understood and properly installed construction hoist lift makes all the difference. If you’re interested in technical guidance or product details for your site, contact us today and let our experts assist you in choosing the most suitable model.

Contact us to learn more about our construction hoist lift solutions and how we can help streamline your construction workflow.