Product Introduction

Frame scaffolding is also called tubular steel frame scaffolding, door style frame scaffolding, is a long established modular frame scaffolding system serving as working platform for construction and decoration purposes, which is composed of main frames, catwalk or walk board, braces or cross braces, brackets, coupling pins of spigot, guardrails and sometimes casters, etc.

1. Highly economic benefit compared with other scaffoldings.

2. Easily assembled and dismantled, saving you plenty of time and labor

3. Pre-galvanized material,more durable

4. Without standards between the bricklayer and the wall-giving full access to the face of the wall.

Product Advantage

Scaffolding is a tool for building projects quickly and efficiently. It can provide a basic structure and some preset configurations to help developers quickly start a new project. Scaffolding has the following characteristics.

1. Fast construction and high efficiency.

2. Unified specifications and standardized packaging.

3. Versatility and early disassembly function.

4. Durability and large bearing capacity.

5. Customizability and cross-platform support.

These characteristics make scaffolding systems widely used and important in construction.

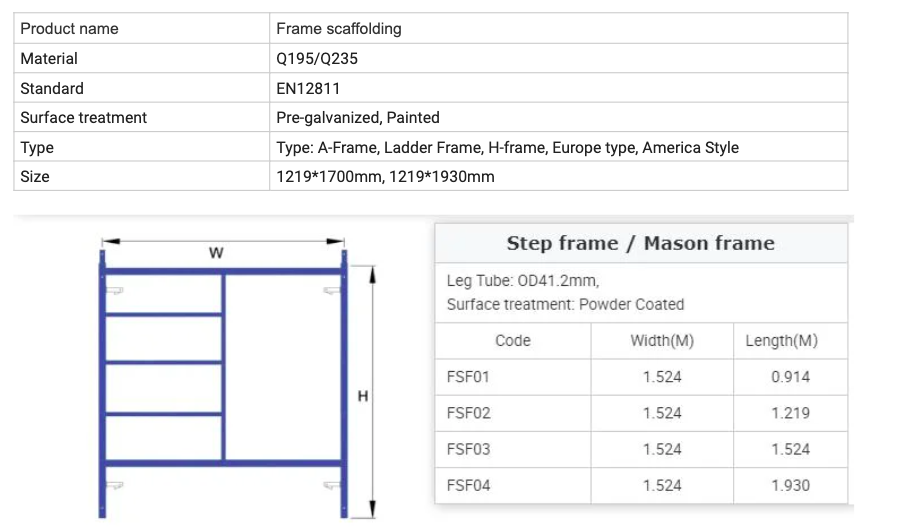

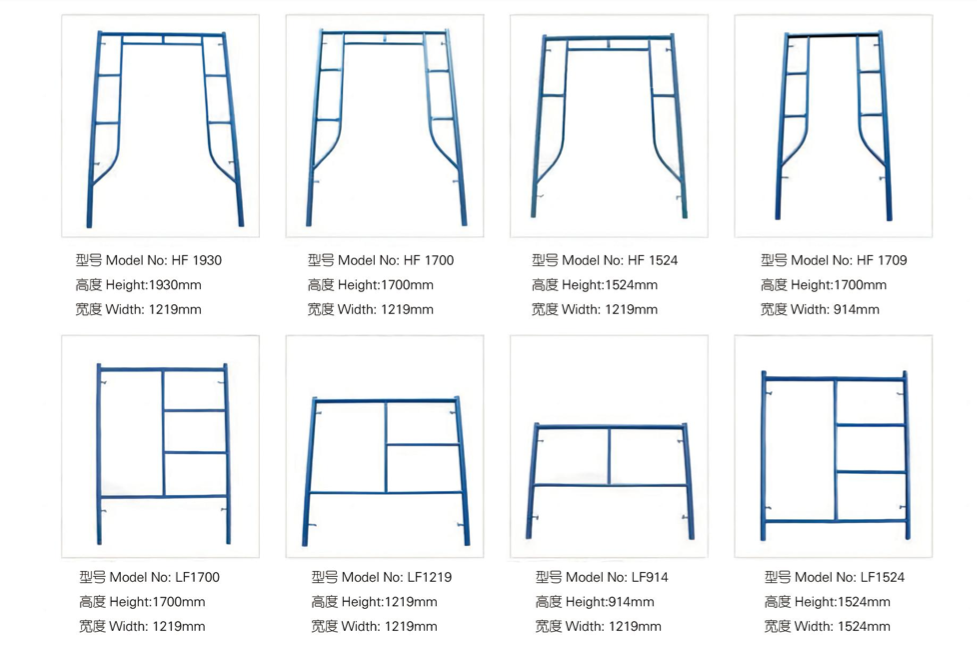

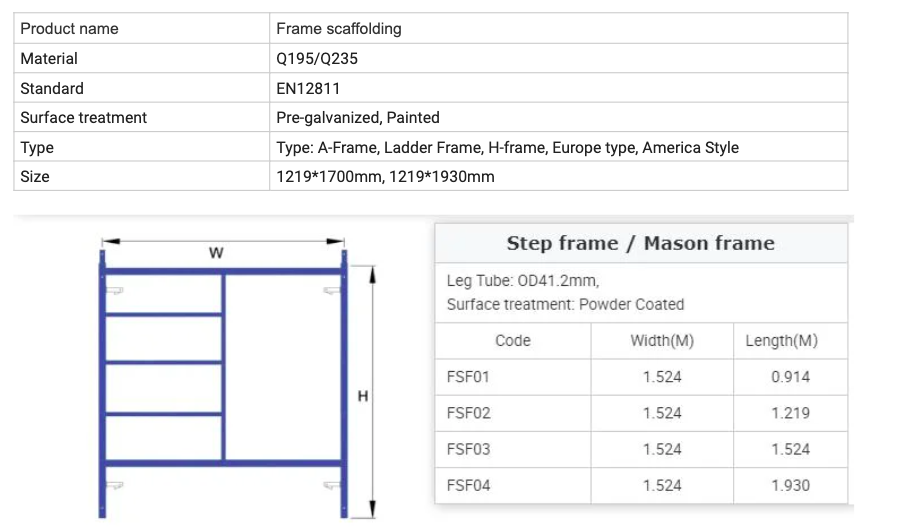

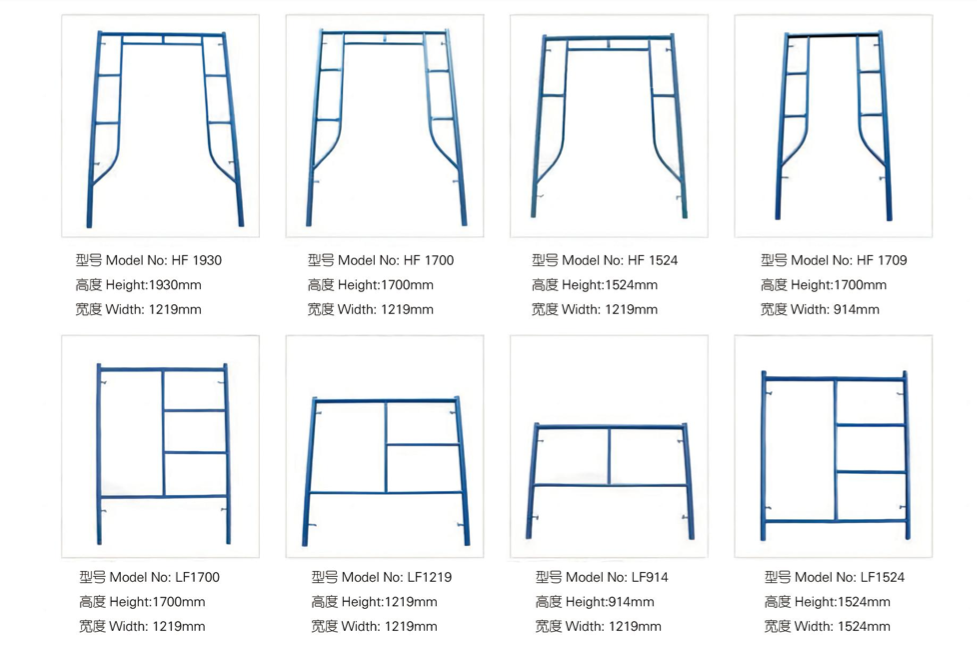

Technical Parameters

Product Uses

The application occasions of scaffolding include but are not limited to:

1. Support design of special plants such as viaducts, tunnel projects, factories, elevated water towers, power plants, and refineries.

2. Construction of overpasses, span scaffolding, storage shelves, chimneys, and water towers.

3. Indoor and outdoor decoration projects, such as the construction of large concert stages, background frames, stands, viewing stands, modeling frames, and stair systems.

4. Construction of stands for sports competitions.

5. In addition, scaffolding also plays an important role in special construction plans such as formwork projects, tower crane foundations and attachment projects, and foundation pit projects. These application occasions not only cover the construction of infrastructure such as buildings, bridges, and roads, but also include temporary projects such as stage construction for large-scale events, which fully demonstrates the importance of scaffolding in modern construction and special event organization.

Product Operate Guide

We provide installation manuals and installation videos.

Before use, please check whether the tower crane functions normally and the safety devices are intact.

During operation, please comply with the specifications and avoid overloading.

Regular maintenance and maintenance to ensure stable operation of the tower crane.

Safety first, ensure smooth construction!

Company profile

GuangYiTong Heavy Industry Machinery Co., Ltd is located in the national pilot Free Trade Zone in Fuzhou, China. It is a comprehensive company, that integrates design, production, sales, and leasing. As a professional manufacturer of construction equipment for more than 20 years, it covers an area of nearly 20000 square meters. The production workshops cover 19, 980 square meters. The company has more than 80 employees, including 28 engineering technical personnel, including 15 technicians with intermediate and senior titles. The company′s product quality is stable, cost-effective, applicable, and high-quality after-sales service, has won a wide range of reputation and has become one high-quality supplier of many well-known construction companies such as MCC, CRCC, CREC, and CSCEC in China and some companies in South America, South Asia, and Europ. In the new coming journey, our company will take "creating high-quality machinery, creating a great enterprise brand "as our goal, advocating the culture of quality management in the whole process of production line of high-quality machinery.

We are looking forward to your sincere cooperation to create a new starting point of wealth.

FAQ

Q1: What are your main products?

A1: We produce all kinds of Construction Hoist 1ton t to 4 tons ; Adjustable prop 3 types; Suspended platform from single seat to 12m; Tower crane with all type; scaffolding and related

Q2: How to confirm a suitable tower crane model?

A2: My dear friends, please tell us the below basic parameters to confirm tower crane model:

a. Building height or tower crane working height.

b. Max load capacity and tip load capacity.

c. Span or jib length

d. Other Special requirements

Q3: Can you install the tower crane or hoist for us

A3: Yes, we can send one engineer to your country for installing, but you should bear the cost.

Q4: Do your products have some certificates?

A4: Yes. Our products have passed CE, ISO, and SGS Certificates.

Q5: What are the payment terms and the delivery time?

A5: Payment terms for building the Construction Elevator Passenger materials hoist are T/T and LC. We will ship the cargo within 20-30 days after receiving the 30% deposit.

Q6: Are you a manufacturer or a trader?

A6: We are a manufacturer with 20 years of maker experience, have an advanced production line and inspection device. Our Research and development team has got a lot of praise from customers.

If you are interested in electric tower crane, please no hesitate to contact us with following parameters:

1. Max crane height under jib ?

2. Working radius?

3. Max load ?

4.Tip load